June 13, 2020. Ted and I bought a hot tub for our anniversary. Oo-la-la, this will be great! Of course, it’s 2020 and the COVID-delayed supply chain has become part of the new normal, so the expected delivery / installation date for our hot tub was August 28. Well, it’s too hot for a hot tub in the summer anyway, and late August will be just in time for the fall weather. Happy anniversary to us!

June 23, 2020. The hot tub salesman told us the concrete company and the electrician will co-ordinate their installation dates with the hot tub delivery date so everything can move forward as soon as the hot tub arrives. We contacted both contractors within a week after our purchase. Since they could be coming soon and the weather was nice (not overbearingly hot or humid July weather), we decided to get the hot tub area ready for the concrete. We picked up the decorative landscaping rock, removed the underlying growth-resistant fabric, and moved the small bush that’s still present in the photo below so everything will be ready for the concrete guys to get to work.

June 25, 2020. The electrician came to our house to determine what he needs to do to wire the hot tub. Of course, we need the maximum amount of wiring. Because the hot tub runs on 240-volt current, it not only requires its own circuit, but the wiring has to be run through conduit. Naturally, the junction box is on one end of the house and the hot tub is on the other end. Running the conduit outside the house is problematic whether it runs along the roofline or along the ground, so it needs to run the length of the house above the drop ceiling in the basement (ground level), then outside through the brick exterior, up to the top of the pergola, across the pergola / patio, back down to the ground, and then about 18 inches over to the hot tub. We signed the contract.

July 15, 2020. All home contractors are super busy this year because people, including us, are staying home and using their travel money for home projects. The concrete contractor finally had time today for a site visit to provide us with a job estimate and a contract. Unbelievable! The concrete pad for our storage shed was poured in 2007 and cost $800 for 80 sq. ft. of 6-inch deep concrete; 13 years later, the hot tub pad cost $2,500 for 64 sq. ft. of 6-inch deep concrete–a 400 percent increase per sq. ft.! We signed the contract. Doug promised to have the concrete poured in time for it to cure before our August 28 expected delivery date.

August 10, 2020. Chad called to let us know, that, due to COVID-related difficulties in obtaining materials and parts, our hot tub delivery date has been re-scheduled for September 19. He said we are lucky because the tub we chose is manufactured in Las Vegas, where COVID isn’t too bad (yet). The manufacturer in Washington state has already closed down for several weeks due to COVID and has no expected delivery dates before early 2021. We decided to continue with our plans to have the concrete poured. Doug has it on his schedule and at least it will be ready in plenty of time for our hot tub delivery.

August 24, 2020. Doug and Tim arrived to pour the concrete. They had to dig down 8 inches–2 inches for a gravel base and 6 inches for concrete strong enough to support the weight of the hot tub (947 lb.) plus 475 gallons of water.

Re-bar had to be laid to prevent the pad from splitting apart if any future cracks develop.

It took a lot of wheelbarrow trips from the truck to the back yard to fill 64 sq. ft. with 6 inches of concrete.

After moving the concrete into place and roughly leveling it, I counted 7 different tools Doug and Tim used to make the surface increasingly smooth. Here’s the last step of smoothing. Tim is checking to make sure Doug doesn’t miss an uneven spot.

September 5, 2020. After waiting for the concrete to cure according to Doug’s instructions, I painted it so it will look nice around the edges of our hot tub. We took paint samples to the hot tub dealer to match paint to the hot tub siding color. There’s plenty of time for the paint to cure before our September 19 delivery date.

September 14, 2020. Chad called to say our hot tub manufacturing date has been delayed until late October or early November. By the time it’s manufactured (about a week), delivered from Las Vegas to St. Louis (another week), and scheduled for installation at our house (another week), we’re probably looking at delivery and installation between November 12 (earliest) and November 19 (latest). Patience is a virtue, right?

November 9, 2020. Chad called to tell us our hot tub has arrived at the dealership and can be delivered November 13. He will contact the electrician so the hot tub can be set up and wired on the same day. Hallelujah!

November 13, 2020. Five months to the day after we ordered it, our hot tub was the first delivery of the day and arrived at its new home around 9:00 a.m.

I was proud of Kevin and his team. They work like me. After unwrapping the hot tub and turning it in the direction we wanted (controls and steps facing the house, captain’s seats facing the pool), they measured both ends of each of the four sides to make sure the tub was centered and square on the concrete. Great job, guys! Looking at an angled, off-center tub for many years would have irritated me every day. This crew was finished after about two hours and moved on to their next delivery / set-up.

Meanwhile, . . . Marcus and Kevin, the electricians, were here an hour before the hot tub delivery to get started on the extensive wiring project. There was a lot of outside measuring, etc. to be done before they started serious work, and it was 33 degrees. Cold! At least it wasn’t cloudy and windy too.

When the delivery crew left, we started filling the tub so Marcus and Kevin could check the electrical hook-ups when they finished. It took them about six hours from start to finish to do the electrical work. They left just as the sunshine came around to the patio and the temperature reached 50 degrees. Reality is starting to sink in: we finally have our hot tub.

Ted and I had cleared a path from one end of the basement to the other so the electrical team could work. We also removed ceiling tiles along the wiring path. We thought that’s what we were supposed to do. When I saw Kevin replacing the ceiling tiles after they finished fishing the conduit and wire across the ceiling, I thanked him and said I hadn’t expected him to do that. “You guys already did a lot more than most people do,” he told me. “Most people just leave everything for us to move.”

Marcus did a brave thing. True, he and Kevin checked and double-checked in the basement and outside before he did the brave thing, but still, . . . He drilled a nearly 1½-inch hole through the outside brick and the concrete basement wall. Of course, it was in exactly the right place on his first try, because he’s a pro. He later admitted that, being no dummy, he drilled a smaller “test” hole just to be sure of his placement before going for the big hole. He works my way too. He said he likes everything to look neat and clean, not just connected, when he’s finished. (The building inspector complimented the electrical work and said it was very “clean.”)

When the interior (flexible) conduit was in place, Kevin starting fishing the wire into the house from the patio and Marcus pulled it across the basement ceiling. There were no hitches. It was “we’re ready” and then the wire went all the way through more than 50 feet of conduit with at least two right-angle turns. Why doesn’t it work that well when Ted and I try to do something similar, but much simpler?

Then came the most interesting part (to me) of the electrical work. I was inside the house and saw Kevin aiming a flaming torch at the rigid exterior conduit. (Some conduit pieces are partially visible at the foot of the ladder in the photo below.) I was curious, so I went outside and asked what he was doing. He was warming the conduit so it would bend to make the 7 turns needed to get from the house to the hot tub. When it was warm enough, the conduit swung and moved as flexibly as a rope. Marcus told me they could also use a hot box, but the torches were better today.

After the conduit became floppy, the two guys moved quickly to put it in place because there was little time to spare before it re-hardened. If more than one bend was needed on the same piece, they usually had to re-warm the area for the second bend. In the second picture below, Marcus is bending the conduit around the pergola post and Kevin is ready to attach the strap to hold it in place. They told me the conduit is paintable, but I’m going to save that project for warmer weather.

Last, it was time to install a dedicated electric box (a dedicated shut-off is required for a hot tub) and fish the wire from the box to the hot tub. The building inspector will be here November 17 to verify that everything is safe. We had to take down our party lights to meet the electrical code because they were within 10 feet of the hot tub. One of the contractors told us (wink, wink) we can re-hang them after the inspector leaves. We promise not to grab the party lights while standing on the hot tub in our wet swimsuits.

By the time all the installation, set-up, and electrical work was finished, the sun was shining warmly on the patio. Ted was busy raking and chipping leaves, and mowing and trimming the lawn for the last time this season, so I checked out how everything works and set up the control panel. The water temperature was 60 degrees. I set it for 104–what Chad told me most people use. It’s possible to set it as low as 50 degrees. Brrrr!–why??? We’ll probably drop it to the pool temperature in the summer so we can go from the pool to the hot tub for a massage and then maybe back to the pool. Fun, fun, fun! Everything is ready to go as soon as the water warms up.

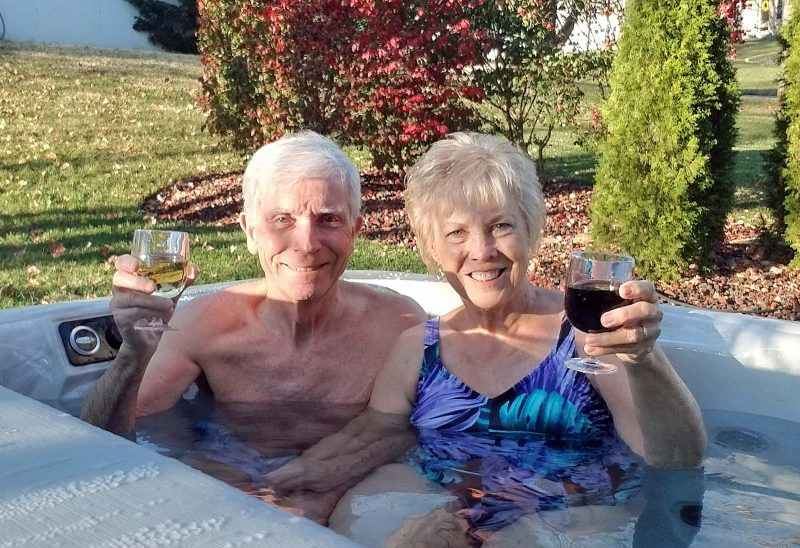

November 15, 2020. The water in the hot tub didn’t warm up in time to enjoy our new toy on its first day at our house, and thunderstorms most of the next day made sitting in a hot tub a risky thing. Probably riskier than grabbing the party lights. Between the showers, however, we balanced the chemical levels of the water, so it wasn’t really a wasted day. Today, Day 3, was a different story. We had a delayed anniversary celebration in our new hot tub.

Note: The white surface in the lower left is the inside of the folded-back hot tub cover. We didn’t slide it all the way off because it provided a nice “table” for our wine glasses.