In March, Ted and I signed a contract to replace our concrete. That contractor backed out in early July and returned our deposit. We signed another contract for the same job and, on August 16, we got The Call: “The crew will be starting the work on your job next week Monday.” It was time to do our prep work–removing and relocating our decorative rock from areas scheduled to be covered with concrete, getting all the outdoor furniture out of the way, moving the firewood, etc. Picking up the rock was the crummiest job. Ted shoveled what he could and I sat on the green gardening mat and tossed all the rock his shovel missed–about a third of it–into the wheelbarrow, which he then dumped into a different (unthreatened) rock bed.

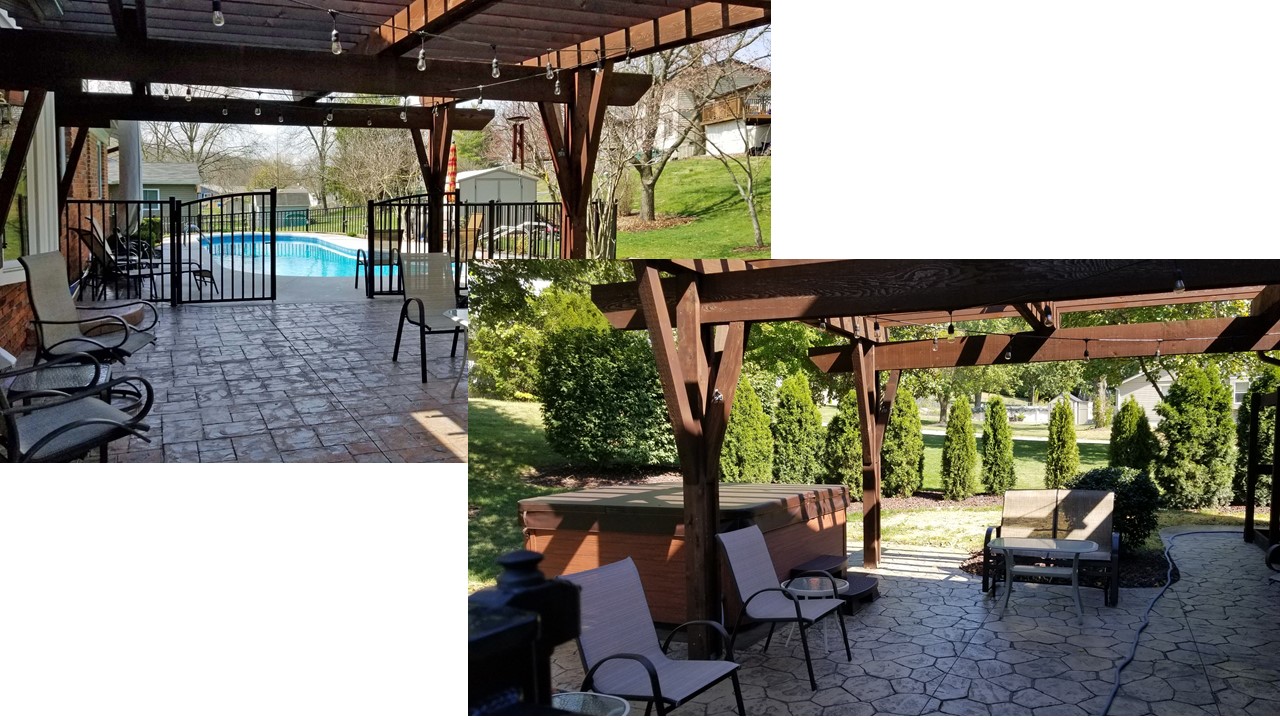

The contractor for the hot tub pad poured a few extra inches on each side so we wouldn’t have to carefully balance the hot tub on the pad. Beginning with the first time we got into the hot tub, we wished we had enough concrete to walk around the hot tub and to slide the cover back without standing in the sometimes wet and (in the winter) always cold grass. We marked a larger area for hot tub concrete. Notice that the beds on each side of the hot tub are bare of rock. Thanks, Ted and Diane.

It didn’t take long to get tired of hearing a jackhammer. When the crew broke up the front porch, the entire house trembled. We might have to watch for cracks in our drywall. When I walked past the dining room door, I noticed a casualty of the jackhammer vibrations.

At the end of the first day, the patio was rubble. Patio party, anyone?

Whenever a concrete truck arrived, the name of the game was “hustle!” A full crew of five guys showed up and everyone moved as quickly as they could. It was impossible to bring the concrete truck into the back yard, so two guys were in charge of toting wheelbarrows filled with concrete from the truck to the patio area. If the guys pushing the concrete into place finished pushing before the next wheelbarrow load arrived, they shouted “Pour!” which I think translated to “Hurry up, we’re waiting for you.” When I complimented the boss on their choreography, he laughed and said, “And we didn’t even bump elbows, did we?” No, they didn’t.

Yes, everyone hustled–except the truck driver. He relaxed while waiting for a wheelbarrow to arrive, then opened the chute to fill the wheelbarrow with concrete. The temperature was in the middle 90s, but this guy didn’t break a sweat.

Dusty opened packages of new stamps and they looked like flowers lying on the lawn. Within minutes, the new stamps were coated with release and looked like the older gray stamps on the left.

Ted and I wanted to watch the stamping process, so we set up a peanut gallery (Howdy Doody reference) for ourselves. In the earlier photo (above), the Christmas-wrapped hot tub looked pretty clean. Not any more. Notice the dust around the crew members as they tamp the stamps into the concrete, forcing the release to poof out in every direction.

The stamps butted against each other like a puzzle. This corner is stamped, and Eddie is putting a stamp marked with texture only–no lines–against the side of the hot tub (upper right). After stamping the texture, Matt and/or Rick used finishing wheels to draw lines by hand in the texture pattern to match the stamps all the way to the edge of the previously installed hot tub concrete.

Ted and I thought the stamping process was dusty, but that was nothing compared to the dust raised when Matt cut the expansion joints. The dust is going higher than the house! This is the day we decided to schedule a power wash company to clean off the house. There’s not much wind, so Dusty (green shirt, standing on the patio at the fence) is visible, even though Matt (using the saw) is not. These guys picked up the broken concrete pieces with bare hands and never wore masks while they worked in all this dust. I can’t help wondering what their lungs look like.

Breaking up the front sidewalks and the driveway was easier because there was room for Matt to use the bobcat. First you lift a section of the sidewalk and break it away from the adjoining sections.

Then you load it onto the forklift.

And then you dump it into the dump truck. The guys filled six dump trucks with concrete rubble plus one trash bag. On this day (and most others) there were trucks with equipment trailers, pickup trucks, and the dump truck parked along the street on both sides of our yard. Add the concrete truck on the days they poured concrete. Our neighbor generously allowed us to park our cars in his driveway for the duration. This was trash day, and Ted and I were looking for a place to put the trash can so the trash pickup guys could find it among all the big trucks. We usually set it where the dump truck is parked. Matt (in the bobcat) saw us with the trash can and said “Put the trash bag in my scoop and I’ll put it in the truck.” Problem solved.

It was disconcerting to open the front door and see a huge concrete truck pulled up to the front porch. Two layers of 3/4-inch plywood covered the area where the truck drove.

There were some concrete glitches. One day, a truck arrived with plain–not colored–concrete, so there was a delay waiting for another truck. The crew filled the time by prepping other areas for the following day. The day the patio was poured, there wasn’t enough concrete to finish the job. The unstamped tan concrete in the photo below shows how much they were short. The tan color is Ted’s and my goal, but the stamped work is currently all charcoal gray with release powder. Matt (the foreman and the owner’s son) assured us that our finished concrete will be tan. It was hard to keep the faith. Unbelievably, people walking by complimented us on how great that gray, powder-covered concrete looked for the week it was curing! Note: Check the dust level on the hot tub now. You can’t even see the hot tub through the (formerly) clear plastic. Picture everything in the yard and on the house similarly covered with release dust.

Here’s Dusty, using the hand wheel to trace all the stamping lines, making sure they are even. I had to take the picture through the window screen to keep out of Dusty’s way.

All the sheet-covered stuff in the left half of the photo below is our outdoor furniture and pool toy shed. When Eddie saw the Star Wars bedsheet, he asked if we have the full set. I told him, “We used to.” It reminded me of a high school field trip Kari’s class took to the Science Center. A Star Wars exhibit was on display and she said everyone was saying “My brother had those sheets.” So did Eddie. The posts on the sawbucks were supporting the front porch roof. As long as they were down, Ted and I decided it would be easy to stain them before the guys re-install them–we just ran a roller over the four flat sides of each post. While we were staining, we noticed that the posts are rotting on the bottoms from sitting on 42 years of rainfall on the porch, so we added “new porch posts” to our to-do list.

The spot where Matt is kneeling has always formed a puddle when it rains, or when Ted washes cars, or when I hose off the driveway. We’ve always had a low spot in the back yard too. Rick (the boss man and owner) suggested a French drain beginning at the low spot in the back yard, then running under the driveway and the front lawn to the street to eliminate the wet area in the back yard and the puddle in the driveway. He connected the driveway drain and both downspouts on this end of the house to the drainpipe. Again, problem solved. In the photo below, Matt asked for a small amount of concrete from the truck and pushed it into place around the drain before they poured the driveway.

Here we have Matt, Eddie, Todd, and Dusty, roughly smoothing the first section of the driveway. They poured the driveway in three parts on three days. The light square in the lower right is the covered drain, safe from the rest of the concrete.

It was interesting to see how the back doorstep was framed. Matt drilled holes for the rebar posts, cut the posts off to be shorter than the finished step, wired them to the frame, and held everything in place with wooden spacers. They’re ready to pour the step.

Lunch break. Most days, the guys had Jimmy John’s for lunch. One day, they skipped lunch because they were busy pouring, smoothing, and stamping a load of concrete. Sometimes they sat in the shade of a tree. On this day, Eddie used the hot tub as a table and the other guys sat on our tipped-over wood rack. The plastic wrapping has been removed from the hot tub at this point. Even with the protection of plastic wrapping, you can see a layer of gray dust on the hot tub cover. For most of the nine days the guys were pouring and stamping, the temperatures were in the mid- to upper 90s and the heat indices ranged from 100-110 degrees. Matt told me that when they removed the protective plastic from the hot tub, they discovered it had melted to itself and they had to cut it off.

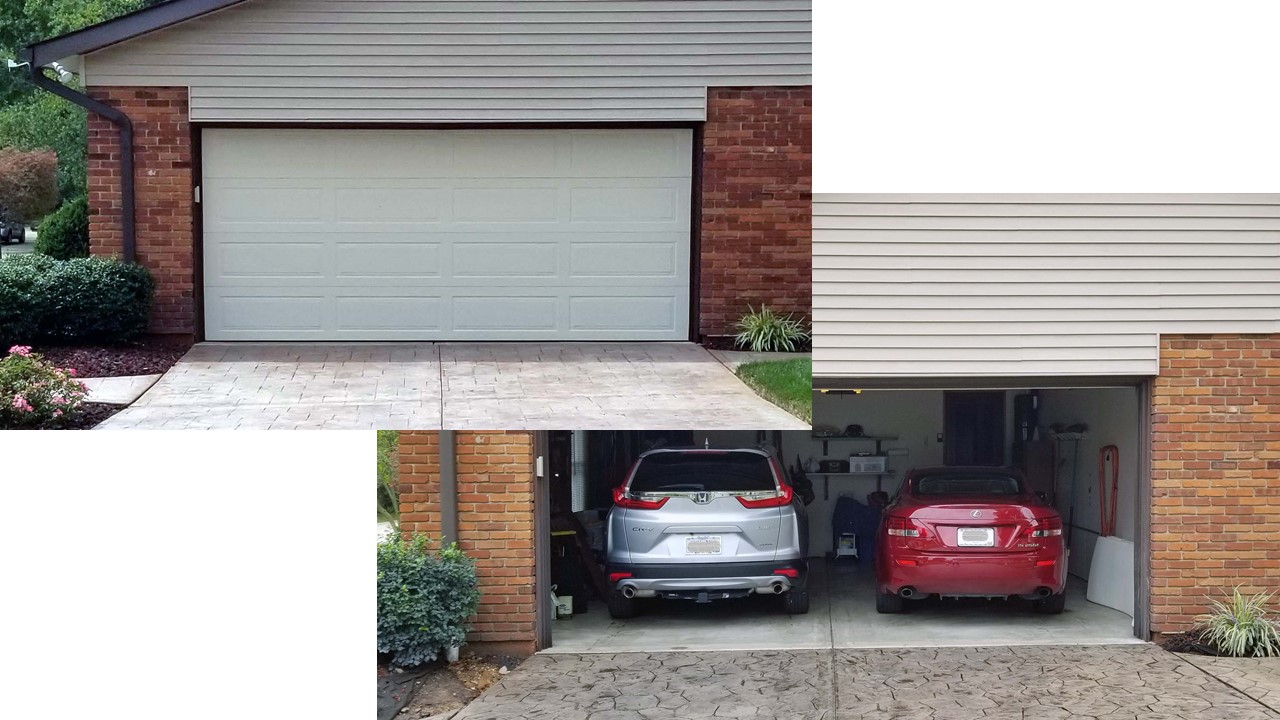

After the last pour, two guys stuck around for an eleven-hour day and hosed the loose release off the dry concrete. The sections poured on this day couldn’t be hosed yet. That’s why the end of the driveway near our cars is more gray than that in the lower part of the photo.

After everything was hosed off, the concrete needed two days to dry so moisture would not be sealed into it Then the sealing process began. It took a crew of three most of two days to apply three coats of seal. The seal added depth to the tan color of the concrete. The first coat was thinned with Xylene to remove any remaining moisture in the concrete. The second coat could be applied within 30 minutes, because the first coat dried so quickly. The third coat was applied more heavily and we were advised not to walk on it for 24 hours. We were allowed to put the lawn furniture back on the patio after 48 hours and to drive the cars into the garage after 72 hours.

First, Ted needed to wash the cars. Both were filthy and his water ran black. They are now touchable again. Note: The newly installed drain worked. There was no car-washing puddle in the driveway. Here’s a before and after photo of the old and the new concrete in the driveway.

And here’s a before-and-after look at the concrete on the patio–from terra cotta rectangles to tan flagstones. Rick (the concrete company owner) stained the edges of the hot tub pad to make them look nicer with the new concrete. You can’t see it in the photo below, but it’s dark brown and provides a decorative contrast to the new tan concrete.

With the fascia, shutters, and windows all updated on the exterior of the house last year and with the new concrete this year, Ted and I decided we needed a new mailbox to complete the fresh look of the house. We wanted a brown mailbox mounted on a stained cedar post with gold-toned house numbers. Apparently, most other people want a black or white plastic mailbox and post with black or silver house numbers. We did a lot of shopping. Mission accomplished. The new mailbox looks better than the old one.

The concrete truck, the digging, the release, and everything else that went with the job created an unbelievable mess. It was a huge relief when the power washing guys came and cleaned everything off so that we now have a touchable outdoor space that we can enjoy again. The old concrete needed to be replaced, the new concrete looks good, and Ted and I are so-o-o-o glad this project is finished. Halleluja!